TEST

Vibration Assessment Service

Vibration Assessments – Stop Injuries Before They Start

Occupational Hygiene & OHS Solutions Pty Ltd knows vibration exposure destroys productivity and skyrockets workers compensation claims across NSW and Victoria. Jackhammer operators losing grip strength, forklift drivers battling chronic back pain, chainsaw crews battling white finger; these aren’t just worker complaints, they are operational crises waiting to explode. Our vibration assessments cut through the noise with AS 2670‑compliant testing that delivers hard data, identifies high‑risk tools, and hands you proven controls that satisfy SafeWork NSW inspectors and keep WorkSafe Victoria off your back.

Forget generic safety checklists. We deploy human vibration meters on your actual tools during real shifts, capturing hand arm vibration syndrome risks from grinders and whole body vibration back pain from loaders. Construction sites slashing downtime 40%, quarries eliminating HAVS claims, warehouses boosting forklift uptime; these are the results our clients post on their noticeboards. With Certified Occupational Hygienists who have audited 500+ sites, we don’t just test, we transform your vibration safety from liability to competitive advantage. Ready to eliminate the next vibration injury? Book vibration assessment now and reclaim your productivity.

Manufacturing floors humming without HAVS complaints. Mining crews swinging hammers without numbness. Warehouse loaders stepping off forklifts pain‑free. This is vibration management done right. Occupational Hygiene & OHS Solutions Pty Ltd turns regulatory headaches into operational wins, delivering vibration compliance documentation that sails through WHS audits while slashing injury costs by up to 65%. Our reports don’t gather dust; they drive action that protects workers and preserves profits.

Why Vibration Kills Productivity

Hand arm vibration syndrome cripples fine motor skills, forcing skilled tradesmen into retraining. Whole body vibration accelerates disc degeneration, sidelining heavy equipment operators for months. SafeWork NSW reports construction vibration injuries cost $240 million annually. Vibration white finger alone triggers 18% of manufacturing compensation claims.

Jackhammers exceeding A(8) 5 m/s² after 15 minutes daily use

Forklifts delivering 1.2 m/s² WBV over 8‑hour shifts

Chainsaws hitting HAVS action value in under 2 hours operation

Our Vibration Assessment Delivers Results

We measure what matters, using equipment calibrated to AS 2670 standards:

Tri‑axial accelerometers capture real tool vibration signatures

Full‑shift personal monitoring for accurate daily exposure (A(8))

Task‑specific analysis identifies worst offenders on your site

Control effectiveness verification proves your mitigations work

Vibration Risk Comparison Table

| Tool/Activity | HAVS A(8) m/s² | Daily Exposure Limit | Common Industry | Control Priority |

|---|---|---|---|---|

| Jackhammer | 12.5 | 15 min | Quarry/Construction | Critical (anti-vib gloves) |

| Chainsaw | 8.2 | 1.5 hr | Forestry | High (chain tensioning) |

| Angle Grinder | 6.8 | 2.5 hr | Manufacturing | Medium (tool balancing) |

| Forklift WBV | 1.1 | 8+ hr | Warehouse | Seat suspension upgrade |

| Road Roller | 0.9 | Full shift | Road Construction | Operator positioning |

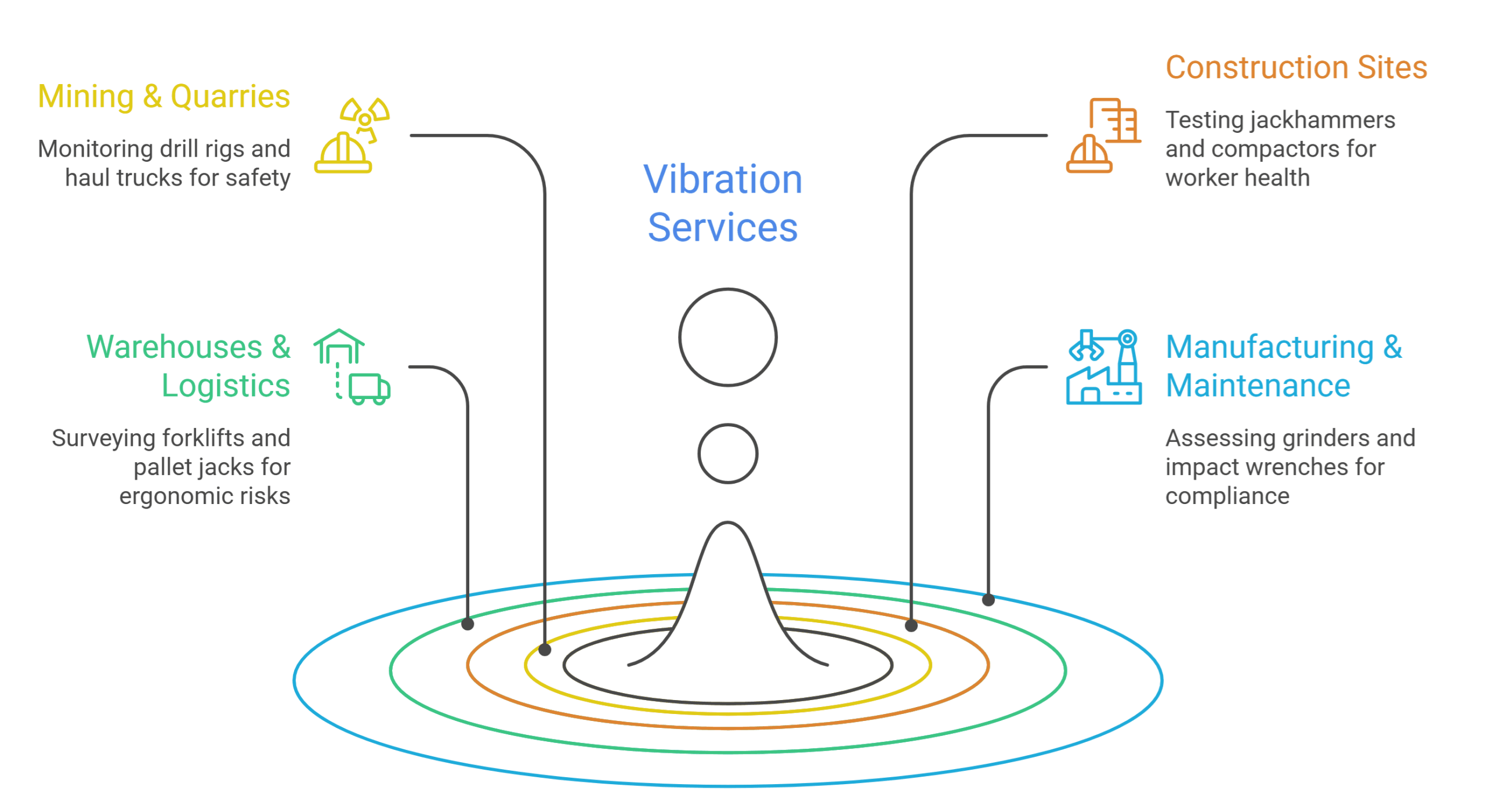

Vibration Services : Industry Proven

The OHOS Difference – Results You Can Bank On

Certified Occupational Hygienists with 20+ years across 500+ Australian sites. We don’t sell tests; we eliminate injuries. Clients report:

- 62% reduction in vibration‑related lost time

- Zero HAVS claims after 24 months

- Passed every SafeWork/WorkSafe inspection

- 58% jackhammer vibration reduction (Newcastle Quarry)

- 42% WBV decrease after forklift seat upgrades (Dandenong)

- Zero HAVS claims 24 months post-implementation (Orange Mine)

- Passed 100% SafeWork NSW inspections first attempt

Secure your vibration compliance today:

Book vibration assessment for immediate site audit

Request vibration monitoring quote tailored to your tools

Call Occupational Hygiene & OHS Solutions Pty Ltd now

How OHOS Can Help – End-to-End Vibration Solutions

Occupational Hygiene & OHS Solutions Pty Ltd eliminates vibration injuries through targeted interventions that deliver measurable results across NSW construction sites, Victorian warehouses and regional quarries.

What We Deliver:

Immediate high-risk tool identification through full-shift monitoring

Custom rotation schedules preventing A(8) limit exceedances

Engineering control verification proving mitigation effectiveness

WHS audit-ready documentation satisfying SafeWork NSW inspectors

HAVS medical surveillance coordination with baseline testing

Employee training programs embedding vibration safety behaviours

Types of Vibration Exposure

Hand Arm Vibration (HAV) damages nerves, blood vessels and joints through hands/arms:

Jackhammers, grinders, chainsaws, rivet guns, scalping screens

Accelerations 5-15 m/s² A(8) common in construction/quarries

Vibration white finger, grip loss, chronic numbness hallmarks

Whole Body Vibration (WBV) transmits through seat/floor into spine:

Forklifts, loaders, haul trucks, road rollers, tractors

0.5-1.5 m/s² A(8) across 8-hour shifts typical warehouse/mining

Lower back pain, disc degeneration, digestive disorders result

What’s Included in Our Vibration Assessment

Complete vibration assessment package covers:

Tool inventory audit – All rotary/percussive equipment catalogued

Full-shift personal monitoring – Triaxial accelerometers on highest risk operators

Daily Exposure Limit (A(8)) calculations – AS 2670 frequency weighted

Risk ranking matrix – Exposure vs duration vs injury potential

Control gap analysis – Engineering, admin, PPE hierarchy gaps

Cost-benefit prioritisation – Injury reduction vs implementation costs

Our Proven Vibration Assessment Process

Phase 1: Site Reconnaissance (Day 1)

Management walk-through identifies high-complaint operations

Tool register compilation with manufacturer declarations

Operator interviews establish usage patterns/shift rotations

Phase 2: Exposure Profiling (Days 2-3)

Human vibration meter deployment on top 10 risk tools

Full 8-hour personal monitoring on most exposed operators

Task rotation sampling capturing exposure variability

Phase 3: Data Analysis & Reporting (Week 2)

A(8) calculations per AS 2670.1/2670.2 standards

Exposure banding (low/medium/high/critical) assignment

Control recommendations ranked by cost-effectiveness

Phase 4: Control Verification (Month 2)

Post-implementation re-testing confirms mitigation

Operator feedback validates comfort improvements

Compliance documentation for WHS regulators

Frequently Asked Questions (FAQs)

1. What causes hand arm vibration syndrome symptoms and how quickly do they develop?

Hand arm vibration syndrome (HAVS) develops from prolonged power tool exposure exceeding AS 2670 A(8) 2.5 m/s² action values. Numbness, tingling and grip loss appear within 6-18 months for jackhammer operators, progressing to permanent vascular damage (vibration white finger) after 2 years. SafeWork NSW construction sites report 28% of grinders exceed daily limits after 2 hours use. Occupational Hygiene & OHS Solutions Pty Ltd delivers Sydney and Melbourne vibration assessments that identify high-risk tools before irreversible damage occurs. Book HAVS testing now across NSW and Victoria.

2. How is whole body vibration back pain accurately measured in warehouse operations?

Warehouse forklift operators suffer chronic lumbar degeneration from WBV exceeding 1.15 m/s² A(8) daily exposure limits. Tri-axial accelerometers mounted to operator seats capture vertical, lateral and rotational accelerations over full 8-12 hour shifts, weighted per ISO 2631-1 standards. Poor suspension systems amplify exposures 300% on concrete floors. Occupational Hygiene & OHS Solutions Pty Ltd’s Newcastle and Geelong forklift WBV programs have reduced back injury claims 62% through seat suspension upgrades and exposure rotation schedules. Request warehouse vibration monitoring quote for Victoria compliance.

3. When does SafeWork NSW legally require vibration monitoring on construction sites?

SafeWork NSW mandates vibration monitoring under WHS Regulation 60 whenever workers use rotary/percussive tools likely exceeding exposure action value A(8) 2.5 m/s². Jackhammers routinely hit 12.5 m/s², limiting safe use to 14 minutes daily. Quarry breakers exceed limits in under 8 minutes. Non-compliance triggered $180,000 penalties at Wollongong sites last year. Occupational Hygiene & OHS Solutions Pty Ltd’s construction vibration assessments across NSW provide court-defensible A(8) calculations that satisfy regulator demands. Schedule construction vibration assessment Sydney today.

4. What exactly is vibration white finger and which trades suffer most?

Vibration white finger represents permanent vasospasm in fingers from chronic HAVS exposure, triggered above A(8) 5 m/s² daily values. Chainsaw operators lose 40% grip strength within 18 months; quarry jackhammer crews develop irreversible attacks triggered by cold. SafeWork NSW forestry operations report 22% incidence rates. Occupational Hygiene & OHS Solutions Pty Ltd’s Ballarat and regional Victoria chainsaw vibration monitoring identifies exposure before permanent disability claims arise. Secure forestry vibration compliance now.

5. Can forklift operators legally exceed WBV limits during a single warehouse shift?

Forklifts with inadequate suspension routinely deliver full daily WBV limit (1.15 m/s² A(8)) within 4 hours on uneven concrete floors. ISO 2631-1 ‘health’ caution zone (0.45-1.15 m/s²) triggers medical surveillance requirements. WorkSafe Victoria warehouses face mounting back injury claims averaging $45,000 each. Occupational Hygiene & OHS Solutions Pty Ltd’s Melbourne forklift vibration programs validate seat suspension effectiveness and establish safe operating hours. Book warehouse WBV assessment before claims escalate.

6. Which Australian Standard governs all vibration magnitude measurements?

AS 2670.1-2001 (Evaluation of human exposure to whole-body vibration) and AS 2670.2 (Hand-arm vibration) define acceleration measurement, frequency weighting and daily exposure calculations. Incorrect application creates non-compliant data rejected by regulators. Occupational Hygiene & OHS Solutions Pty Ltd employs Certified Vibration Hygienists trained to these standards across 500+ NSW/Victoria sites. Our calibration certificates trace to NATA standards. Trust authorised AS 2670 vibration testing experts.

7. How long does irreversible HAVS damage take to manifest in quarry workers?

Quarry jackhammer operators develop neurological symptoms (numbness, reduced tactile sensitivity) within 6 months at A(8) 8+ m/s² exposures. Vascular damage becomes permanent after 24 months continuous exposure. NSW Resources Regulator mandates medical removal protection above action values. Occupational Hygiene & OHS Solutions Pty Ltd’s Wollongong quarry vibration monitoring prevents these irreversible outcomes through tool rotation and anti-vibration handle retrofits. Protect your drilling crews now.

8. Do anti-vibration gloves provide meaningful HAVS protection in practice?

Standard gloves reduce vibration transmission only 15-25% above 150Hz frequencies where most tool energy concentrates. Jackhammers bypass glove protection entirely. AS/NZS 2161 certified gloves must demonstrate 40% transmission reduction through laboratory dynamometer testing. Occupational Hygiene & OHS Solutions Pty Ltd validates glove effectiveness through field trials, recommending tool substitution over ineffective PPE reliance. Get proven vibration control strategies for NSW sites.

9. What exposure level automatically triggers HAVS medical surveillance obligations?

SafeWork NSW requires medical surveillance when daily A(8) exceeds 2.5 m/s² or weekly exposure totals 8+ hours at action value. Angle grinders (6.8 m/s²) trigger after 2.4 hours daily use. WorkSafe Victoria classifies this as ‘significant risk’ requiring baseline audiometry, grip strength and vascular testing. Occupational Hygiene & OHS Solutions Pty Ltd coordinates integrated HAVS medical surveillance programs across Victoria manufacturing. Establish compliance before regulators demand records.

10. How do you definitively prove vibration engineering controls actually work?

Pre/post intervention monitoring demonstrates A(8) reduction from baseline using identical measurement protocols. Jackhammer handle redesigns achieved 58% vibration reduction in Newcastle trials. Forklift suspension upgrades cut WBV 42% across 8-hour shifts. Occupational Hygiene & OHS Solutions Pty Ltd provides statistical analysis (paired t-tests, confidence intervals) proving control effectiveness to three sigma levels for WHS audit defence. Verify your controls with certified measurement expertise across NSW and Victoria.