Noise and Vibration in the Workplace: Modern Approaches to Risk Assessment and Mitigation in Australia

Scene Setter: A Day in the Life

Imagine standing on a bustling factory floor. Machines hum, forklifts beep, and the air vibrates with energy. But beneath this productivity, invisible risks—noise and vibration—threaten the long-term health of every worker.

Why It Matters: The Hidden Impact. Did you know?

- Over 28% of Australian workers are regularly exposed to hazardous noise levels.

- Vibration-related injuries cost businesses millions in lost productivity and compensation each year

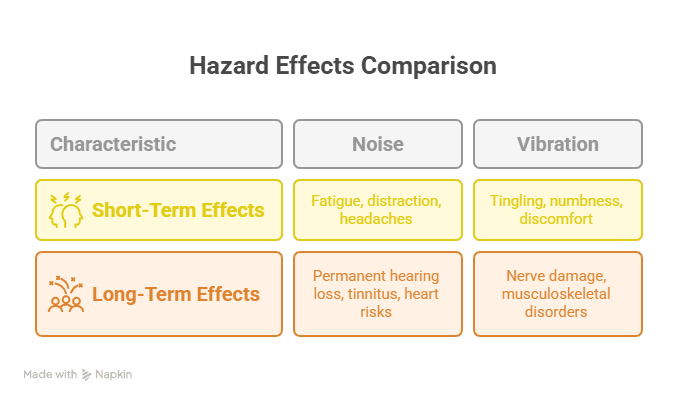

Health Effects: What’s at Stake?

Interactive Checklist: Is Your Workplace at Risk?

- Do workers raise their voices to communicate at 1 metre?

- Are vibrating tools used for more than 2 hours a day?

- Has anyone reported ringing in their ears after a shift?

- Are there complaints of hand numbness or tingling?

If you answered “yes” to any, your workplace may be at risk.

Regulatory Spotlight: What’s New for 2025?

Key Legal Duties for Employers (PCBU)

- Hazard Identification: Inspect for noisy equipment and tasks; consult with workers and review injury trends.

- Risk Assessment: Conduct noise and vibration assessments using calibrated equipment and exposure calculators.

- Exposure Standards:

- Noise must not exceed 85 dB(A) averaged over 8 hours, or 140 dB(C) peak.

- For workers exposed to certain substances, the standard is reduced to 80 dB(A).

- Audiometric Testing:

- Required within 3 months of starting work with hazardous noise, then at least every 2 years.

- Control Measures:

- Prioritise elimination, substitution, and engineering controls before PPE.

- Maintain and review all controls regularly.

- Worker Duties:

- Follow safety instructions, use PPE correctly, and report any symptoms or unsafe conditions.

The OHOS Approach: Expert Help, Every Step

How Occupational Hygiene & OHS Solutions (OHOS) Pty Ltd Supports You:

- On-Site Exposure Monitoring: Using calibrated dosi meters and dosimeters for real-time data.

- Custom Risk Assessments: Tailored to your industry, shift patterns, and equipment.

- Actionable Control Plans: Engineering solutions, PPE programs, and administrative controls.

- Worker Health Surveillance: Audiometric and vibration health checks.

- Compliance Audits: Ensuring you meet AS/NZS 1269, AS 2670, and Safe Work Australia standards.

- Management Training: Building internal capacity for ongoing risk management.

Your Next Steps: Take Action Today

- Schedule a workplace noise and vibration assessment.

- Review your current controls and training programs.

- Contact OHOS for a tailored consultation and ongoing support.

Ready to protect your team and your business?

Contact OHOS for industry-leading expertise and practical solutions.