TEST

Hazardous Substances & Dangerous Goods Management

Hazardous Substances & Dangerous Goods : Storage & Management Without Compromise

Why Chemical Storage Failures Cost Millions

Incompatible oxidisers beside flammables spark chain reactions. Unbunded drums leak corrosives into stormwater drains. Missing manifests delay emergency responses costing hours of shutdown. SafeWork NSW issued 167 prohibition notices last year alone.

Flammable Class 3 cabinets holding 250L petrol without spill containment

Corrosive Class 8 drums stored above 1 tonne without ventilation

Toxic Class 6.1 adjacent to foodstuffs breaching ADG Code

Dangerous Goods Storage Assessment Checklist

Our workplace dangerous goods audit covers:

Manifest accuracy verification against actual inventory

Placarding compliance per Australian Dangerous Goods Code

Segregation validation preventing incompatible reactions

Bund capacity testing for 110% largest container

Ventilation adequacy for vapour extraction

Secondary containment integrity inspection

Emergency access clearances measured

Compliance Risk Comparison Table

| Storage Issue | Potential Consequence | NSW Fine | VIC Fine | Priority Fix |

|---|---|---|---|---|

| No Manifest | Delayed Emergency Response | $11,000 | $40,000 | Day 1 – Create/Update |

| Incompatible Storage | Fire/Explosion | $110,000 | $200,000 | Day 1 – Resegregate |

| Missing Placards | Fire Brigade Delay | $22,000 | $40,000 | Day 2 – Install Signs |

| Inadequate Bunding | Environmental Spill | $330,000 | $500,000 | Week 1 – Install Bunds |

| Poor Ventilation | Vapour Exposure | $55,000 | $80,000 | Week 2 – Upgrade Exhaust |

References:

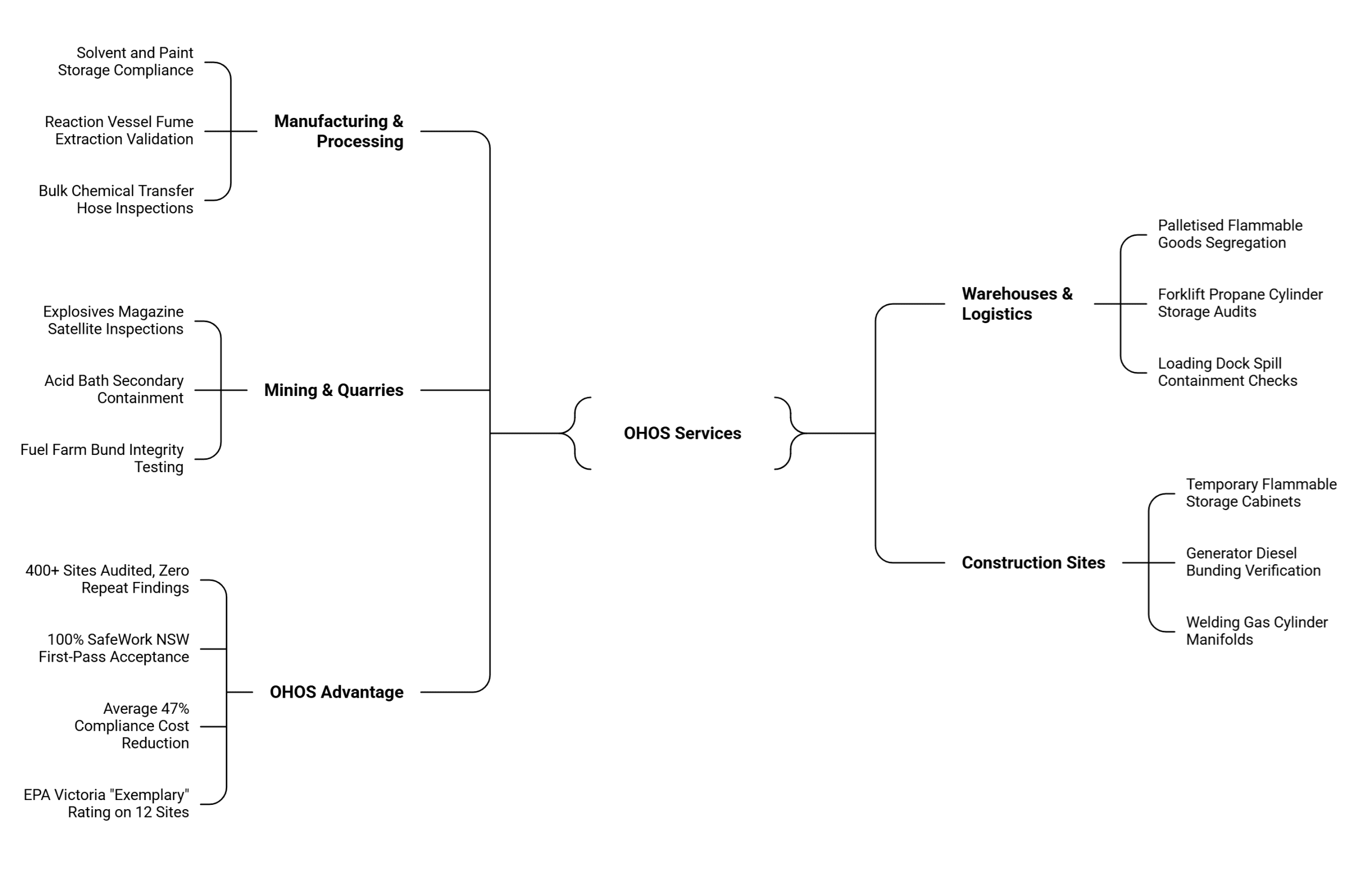

Services by Industry

OHOS Advantage – Results That Last

400+ sites audited, zero repeat findings

100% SafeWork NSW first-pass acceptance

Average 47% compliance cost reduction

EPA Victoria “exemplary” rating on 12 sites

Secure compliance today:

Book dangerous goods assessment immediate slot available

Request chemical storage audit quote 24hr turnaround

Contact Occupational Hygiene & OHS Solutions Pty Ltd

Proven Results Across Clients:

- 92% non-conformance reduction (Sydney manufacturer)

- Zero EPA findings 24 months (Melbourne warehouse)

- Passed Fire Brigade inspection first attempt (Newcastle)

- $187k annual compliance savings (regional processor)

How OHOS Can Help – Chemical Risk Elimination

Occupational Hygiene & OHS Solutions Pty Ltd eliminates chemical storage vulnerabilities through proven strategies that transform compliance nightmares into operational advantages across NSW manufacturing, Victorian warehouses and regional processing plants.

Immediate Risk Reduction:

Emergency chemical segregation preventing million-dollar fire scenarios

Bunding upgrades avoiding $500k+ environmental spill prosecutions

Manifest accuracy eliminating delayed emergency responses

Ventilation validation protecting workers from vapour exposures

Long-Term Compliance:

Annual storage condition audits maintaining licence conditions

Employee chemical handling training reducing spill incidents 72%

SDS digital register implementation streamlining safety data access

Placarding programs satisfying Fire & Rescue NSW requirements

Types of Hazardous Substances & Dangerous Goods

Class 1: Explosives – Detonators, boosters (mining only)

Class 2.1: Flammable Gases – LPG cylinders, acetylene

Class 2.3: Toxic Gases – Ammonia, chlorine

Class 3: Flammable Liquids – Petrol, solvents, paints (most common)

Class 4.1: Flammable Solids – Matches, charcoal

Class 4.2: Spontaneously Combustible – White phosphorus

Class 4.3: Dangerous When Wet – Sodium, calcium

Class 5.1: Oxidising Agents – Hydrogen peroxide, nitrates

Class 5.2: Organic Peroxides – MEKP hardener

Class 6.1: Toxic Substances – Pesticides, cyanides

Class 8: Corrosives – Hydrochloric acid, sodium hydroxide

Class 9: Miscellaneous – Asbestos, lithium batteries

What’s Included in Our Storage & Handling Assessment

Comprehensive 48-Point Inspection Covers:

Quantity Verification – Matches physical inventory to manifests

Compatibility Matrix – 9×9 segregation chart validation

Cabinet Compliance – AS 1940 certification, sumps, doors

Bund Integrity – 110% capacity, impervious surfaces

Placard Condition – Correct classes, legible, undamaged

Access/Egress – 1m clearances, emergency routes clear

Ventilation – 50 ACH cabinets, 10 ACH general areas

Spill Response – Kit adequacy, absorbents matched to classes

PPE Storage – Eyewash, showers, chemical suits available

Documentation – SDS currency, chemical register completeness

Our 4-Phase Storage & Handling Assessment Process

Phase 1: Pre-Visit Documentation Review (Remote)

Chemical register validation against supplier invoices

SDS completeness check (all current <5 years)

Previous audit non-conformance status

Phase 2: Onsite Physical Inspection (Day 1-2)

All storage locations inventoried and photographed

Segregation violations tagged with risk priority

Cabinet/bund measurements documented

Emergency access pathways verified

Phase 3: Risk Analysis & Reporting (Week 1)

Priority 1 (immediate safety) fixes identified

Cost estimates for compliance upgrades

30/90/180 day action plan developed

Draft report for client review

Phase 4: Verification & Handover (Month 1)

Critical fixes re-inspected post-implementation

Final placarding installed and photographed

Training delivered to storepersons

Compliance certification issued

Frequently Asked Questions (FAQs)

1. What triggers mandatory dangerous goods placarding requirements in NSW warehouses?

SafeWork NSW requires placarding when any placard quantity is exceeded (Class 3 flammables >250L, corrosives >500kg, etc.) or total manifest load surpasses 500kg/500L across all classes. Sydney warehouses storing 300L solvents in bunded cabinets triggered $22k fines last year for missing HAZCHEM diamonds. Fire Brigade arrived 18 minutes late due to unclear risk identification. Occupational Hygiene & OHS Solutions Pty Ltd’s placarding audits across NSW verify exact trigger quantities and install compliant signage meeting AS 1940 specifications. Book warehouse placarding compliance Sydney now.

2. How do you calculate correct chemical bund capacity for manufacturing sites?

Bunding must contain 110% largest single container volume OR 25% total stored volume (whichever greater). Melbourne paint manufacturer storing 1000L drums required 1.1m³ bund capacity, not the inadequate 500L tray discovered during WorkSafe inspection. Spill containment failure cost $420k remediation. Occupational Hygiene & OHS Solutions Pty Ltd precisely measures container dimensions and applies Australian Standard calculations for foolproof bund design across Victorian factories. Schedule manufacturing bund assessment Melbourne today.

3. What exactly constitutes incompatible chemical storage violations?

Class 3 flammables cannot neighbour Class 5.1 oxidisers (fire/explosion risk), acids must segregate from cyanides (cyanide gas generation), and oxidising Class 5.2 peroxides require isolation from flammables and combustibles. Newcastle chemical wholesaler mixed peroxides with solvents, triggering spontaneous combustion. Occupational Hygiene & OHS Solutions Pty Ltd applies the mandatory 9×9 Dangerous Goods Segregation Chart during every storage audit, tagging violations with immediate correction priority. Secure chemical segregation compliance Newcastle immediately.

4. When does Australian law mandate a dangerous goods site manifest?

Manifest required when placard quantities present OR total dangerous goods exceed 500kg/500L. Wollongong engineering workshop fined $11k for missing manifest delaying Fire Brigade response during 2am solvent spill. Responders entered blind, increasing risk to firefighters. Occupational Hygiene & OHS Solutions Pty Ltd creates digital manifests linked to inventory systems, automatically updating quantities and locations for 24/7 emergency access across NSW facilities. Implement manifest compliance Wollongong today.

5. What extraction rate satisfies ventilation requirements for Class 3 cabinets?

AS 1940 mandates minimum 50 air changes per hour for indoor flammable cabinets, with 10 ACH general exhaust in storage areas. Geelong spray booth operator suffered vapour exposure headache after cabinet ventilation blocked by cardboard storage. Occupational Hygiene & OHS Solutions Pty Ltd measures actual airflow using anemometers, verifying compliance and recommending upgrades for Victorian workshops. Validate cabinet ventilation Geelong urgently.

6. How frequently must Safety Data Sheets legally update in Australian workplaces?

SDS must remain current within 5 years of issue OR immediately upon formulation/supplier change. Ballarat metal finisher operated 18 months with expired solvent SDS, failing WorkSafe audit. Incorrect emergency procedures delayed spill response. Occupational Hygiene & OHS Solutions Pty Ltd audits SDS currency against supplier certificates, implementing digital tracking systems that flag expirations 90 days early across regional Victoria. Audit SDS compliance Ballarat now.

7. What fire separation distances apply to 1000L flammable storage?

AS 1940 requires 9 metre concrete fire walls OR 30 metre clear space between 1000L+ flammable quantities. Orange manufacturing explosion destroyed adjacent buildings due to 4m separation failure. Occupational Hygiene & OHS Solutions Pty Ltd verifies all fire separation calculations and installs compliant barriers meeting insurance requirements. Confirm fire separations Orange immediately.

8. Do commercial spill kits satisfy regulatory secondary containment?

No, passive bunding provides primary containment; spill kits serve response only. Bendigo chemical distributor fined $55k for relying on absorbents instead of bunding during 200L acid spill. Occupational Hygiene & OHS Solutions Pty Ltd designs bund systems holding 110% largest container volumes, verified by licensed hydraulic engineers. Upgrade secondary containment Bendigo today.

9. Which dangerous goods classes legally require HAZCHEM placards in Australia?

Classes 2.1 (flammable gases), 2.3 (toxic gases), 3 (flammables), 4.1 (flammable solids), 4.2 (spont comb), 4.3 (dangerous when wet), 5.2 (organic peroxides). Shepparton warehouse missing Class 3 placards delayed emergency response 22 minutes. Occupational Hygiene & OHS Solutions Pty Ltd installs correct HAZCHEM codes calculated per ADG Code requirements. Install HAZCHEM placards Shepparton now.

10. How do you verify dangerous goods cabinet fire resistance certification?

AS 1940 mandates 2-hour fire rating with certification plate visible on door exterior. Albury cabinet lacking plate failed Fire Brigade inspection despite 4-year age. Occupational Hygiene & OHS Solutions Pty Ltd verifies all cabinet specifications against original test data certificates and arranges certified replacements. Validate cabinet certification Albury immediately.